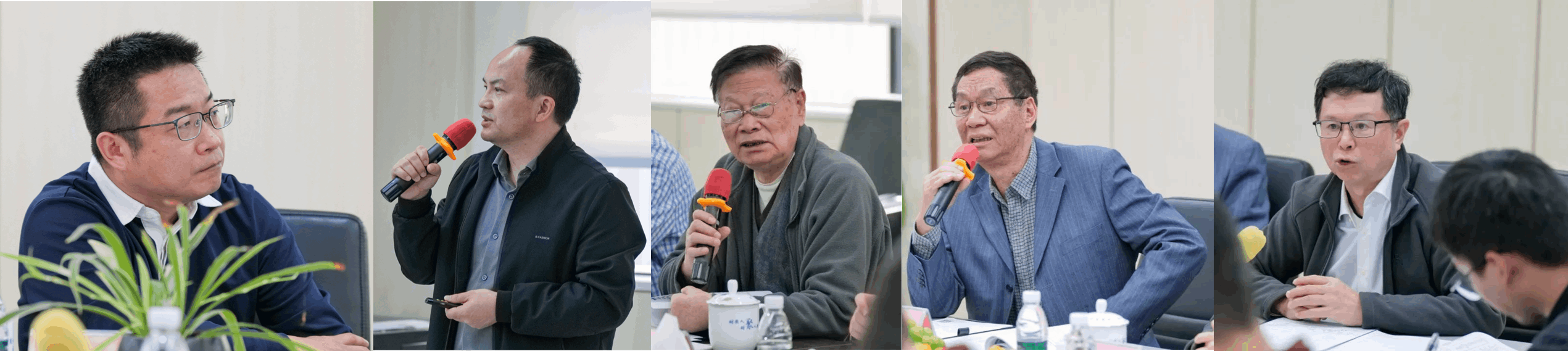

On December 29th, the Guangdong Building Materials Industry Association and Guangdong Ceramics Association conducted a certification meeting at Foshan KEDA Industrial Co., Ltd. for the new product and technology titled "Key Technology R&D and Industrialization of High-Efficiency and Energy-Saving Intelligent Control for Lepidolite Roasting Tunnel Kiln". The appraisal committee, composed of industry experts, unanimously acknowledged that Foshan KEDA Industrial Co., Ltd.'s "Tunnel Kiln Roasting Lepidolite Technology" has reached an internationally leading level.

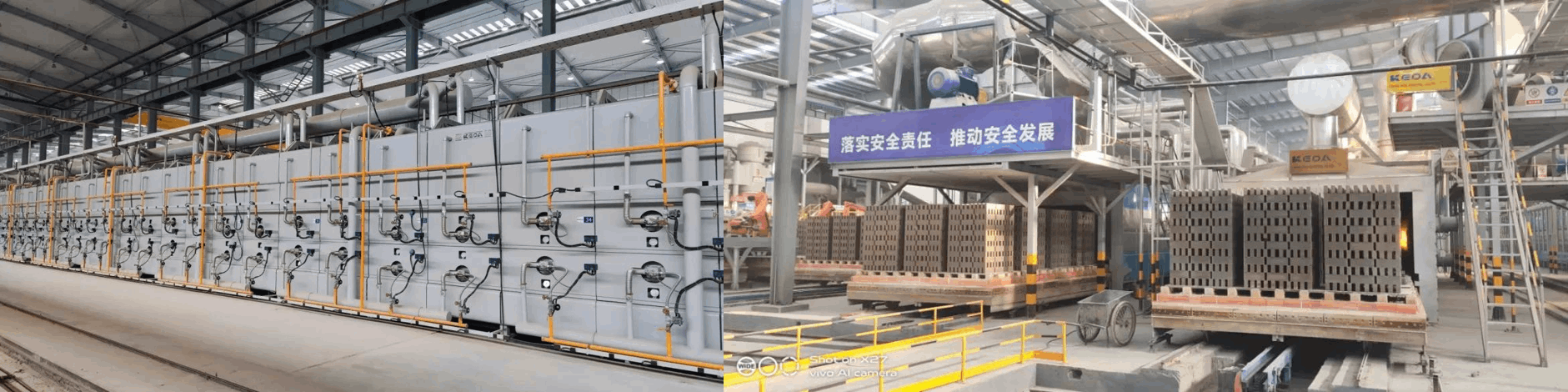

Foshan KEDA Industrial Co., Ltd. has introduced an innovative approach to the roasting process of low-grade lithium ores, such as lepidolite, by employing the tunnel kiln full-salt method solid-phase roasting technology. The project optimizes the kiln structure based on the roasting mechanism of lepidolite. It incorporates various technical measures, using the proportional spray gun layout, double kiln door closed system, specially designed lightweight kiln cars, optimized stacking methods, flue gas waste heat recovery system, corrosion-resistant air ducts and inner kiln walls, and a new generation of big data control systems. These measures collectively contribute to a significant improvement in lithium conversion rates, a reduction in energy consumption, and an extension of the kiln's service life.

The project has secured 1 authorized invention patent, 8 utility model patents, and 2 software copyrights, establishing independent intellectual property rights. The lepidolite roasting tunnel kiln, boasting a daily production capacity of 1,260 tons, attains an impressive lithium salt conversion rate exceeding 93%, with a natural gas consumption of less than 60 Nm3/T. In comparison to traditional rotary kilns, the lithium leaching rate and energy-saving benefits are notably substantial.

The High-Efficiency and Energy-Saving Intelligent Control for Lepidolite Roasting Tunnel Kiln

Since 2017, Foshan KEDA Industrial Co., Ltd. has been at the forefront of applying tunnel kilns in the lepidolite roasting segment within the Chinese lithium-ion battery industry. Through in-depth research across the complete process, the company has developed expertise in the process layout and planning design of the complete plant and complete production line. As of now, Foshan KEDA Industrial Co., Ltd. has successfully completed the construction of 10 lithium-ion battery production lines, supplying lithium-ion battery manufacturing machinery to several listed companies in the lithium-ion battery sector, including Kanglongda (603665), Yongxing Materials (002756), and Willing New Energy (002667).

Looking ahead, Foshan KEDA Industrial Co., Ltd. remains committed to technological innovation, spearheading the technological and industrial advancement of the lepidolite ore lithium extraction industry with a spirit of exploration and innovation. The company aims to drive the entire industry towards greener, low-carbon, and high-quality development.

(Foshan KEDA Industrial Co., Ltd.)

loading...

loading... 15 Jan 2024

15 Jan 2024