Recently, there's good news from Kajaria Ceramic, India's leading ceramic brand. The second sanitary ware tunnel kiln, constructed by DLT, for Kerovit Global, a Kajaria Ceramic subsidiary located in the Morbi region of Gujarat, India, has been successfully ignited.

This kiln primarily produces high-end sanitary ware products, with a daily output of 2,288 pieces, serving both domestic and international high-end consumer markets in India.

The successful ignition ceremony indicates Kajaria Ceramic's ongoing expansion in the ceramic industry, significantly enhancing the production capacity of India's leading brand in the high-end sanitary ware sector.

It also reflects the effectiveness of the "green solution" in fostering high-quality development and promoting new productivity in India's ceramic industry in the new era.

The ignition ceremony was well-attended by Kajaria Ceramic leadership, including Executive Director Mr. Rishi Kajaria, alongside Kerovit Global management and employee representatives. The local HLT&DLT team was also present. The traditional ceremony included prayers as the kiln fire blazed, symbolizing auspiciousness, peace, prosperity, and flourishing.

The ignition ceremony was well-attended by Kajaria Ceramic leadership, including Executive Director Mr. Rishi Kajaria, alongside Kerovit Global management and employee representatives. The local HLT&DLT team was also present. The traditional ceremony included prayers as the kiln fire blazed, symbolizing auspiciousness, peace, prosperity, and flourishing.

The ignition ceremony was well-attended by Kajaria Ceramic leadership, including Executive Director Mr. Rishi Kajaria, alongside Kerovit Global management and employee representatives. The local HLT&DLT team was also present. The traditional ceremony included prayers as the kiln fire blazed, symbolizing auspiciousness, peace, prosperity, and flourishing.

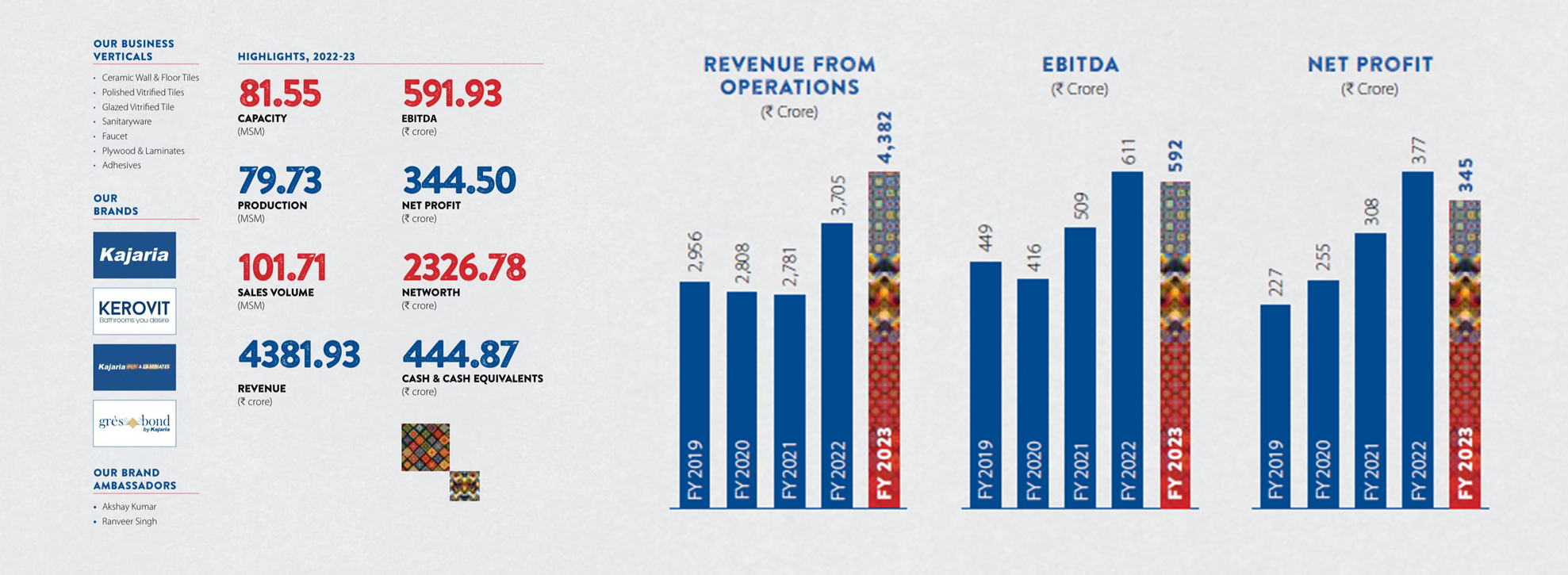

The ignition ceremony was well-attended by Kajaria Ceramic leadership, including Executive Director Mr. Rishi Kajaria, alongside Kerovit Global management and employee representatives. The local HLT&DLT team was also present. The traditional ceremony included prayers as the kiln fire blazed, symbolizing auspiciousness, peace, prosperity, and flourishing.Kajaria Ceramic, a prominent brand in India's tile industry and a listed company, was founded in 1988. It ranked seventh in Ceramic World Review's 2021 annual global ranking of top tile manufacturers. Recognized as a world super brand for 12 consecutive years, it boasts an annual production capacity of nearly 85 million square meters.

Kajaria Ceramic currently operates 8 major production bases across India, including Sikandrabad in Uttar Pradesh, Gailpur and Malootana in Rajasthan, Vijayawada and Srikalahasti in Andhra Pradesh, and Balanagar in Telangana, along with 2 factories in Gujarat. They maintain a network of over 1700 dealers.

In its 36-year journey, Kajaria Ceramic has prioritized innovation and production in the ceramic tile industry. Its annual production capacity has grown from 1 million square meters initially to the current 85 million square meters, meeting consumer demands and market trends effectively.

With over 3000 varieties of creatively designed ceramic wall tiles, floor tiles, and vitrified tiles, Kajaria Ceramic has become synonymous with superior quality, efficient service, and innovative design in both Indian and international markets.

In 2023, Kajaria Ceramic achieved a production output of 79.73 million square meters, with sales totaling 101.71 million square meters. This resulted in a revenue of 43.8193 billion rupees and a net profit of 3.445 billion rupees. Notably, sanitary ware product revenue amounted to 3.16 billion rupees, comprising 7% of the total revenue and marking a 15% increase compared to 2022.

Kerovit Global, a subsidiary of Kajaria Ceramic, specializes in high-end sanitary ware products known for their innovative, technology-driven approach. The company employs highly automated and intelligent production management systems.

As India's leading brand in the ceramic industry and a publicly listed company, Kajaria Ceramic maintains stringent requirements for its production machinery. DLT, driven by meeting customer and market demands, aims to provide high-quality thermal machinery by benchmarking against the industry's most advanced technological standards. DLT continuously innovates and reforms to meet these standards.

DLT is committed to leading and demonstrating clean production, intelligent manufacturing, and high-quality development in the ceramic industry.

DLT's construction of the sanitary ware tunnel kiln represents the pinnacle of high-quality kiln furnaces. This new kiln builds upon the success of its predecessor, undergoing scientific optimization, high-end configuration, and strict adherence to international environmental standards.

It offers benefits such as a wide automatic temperature adjustment range, low comprehensive energy consumption, and high automation. Notably, it incorporates the latest DBS energy-saving combustion system, maximizing air circulation within the kiln to consume residual oxygen and ensuring complete gas combustion while reducing external air supply.

This results in reduced energy consumption and maintains firing atmosphere stability, achieving environmentally friendly and energy-saving ceramic production. Additionally, another shuttle kiln is undergoing intense preparation and will soon be operational.

Throughout its journey, HLT&DLT has become a strong presence in the rapidly evolving Indian market, fueled by its strong local team, extensive manufacturing experience, and high-quality complete production line machinery. The company has received enthusiastic praise from numerous satisfied customers due to its successful projects and sterling reputation.

Moving forward, HLT&DLT is committed to strengthening cooperation with Kajaria Ceramic in various directions, aiming for higher levels of mutual cooperation and win-win outcomes. This contributes to advancing the ceramic industry in India.

The ignition ceremony perfectly complements the theme of HLT&DLT's exhibition at Uniceramics Expo on April 18th, "Green Technologies for Smart Plant". HLT&DLT extends a warm invitation to everyone to visit booths (Hall 7: 745&746) and discover the latest technological advancements, while engaging in discussions about the ceramic industry's development trends.

(HLT&DLT)

loading...

loading... 10 Apr 2024

10 Apr 2024