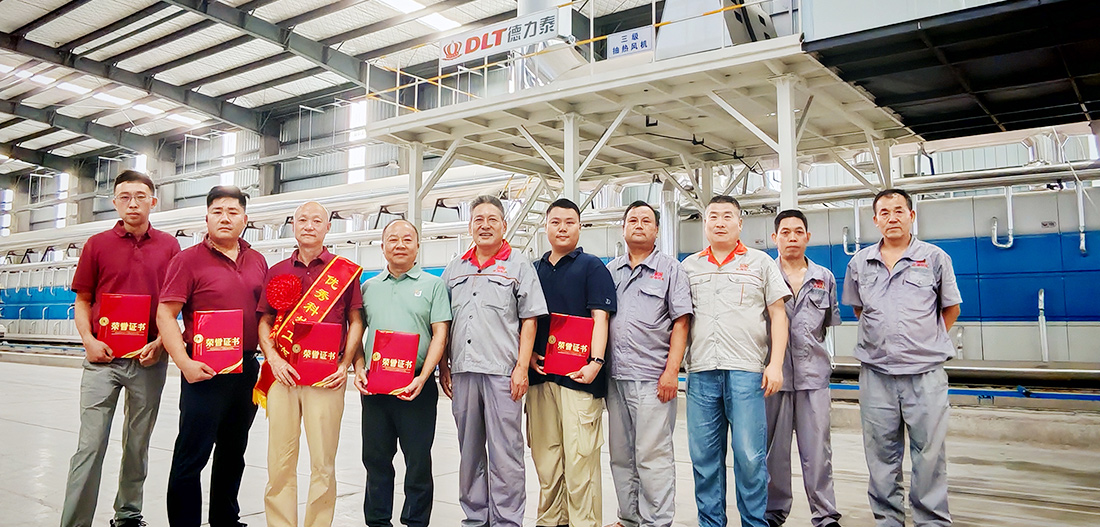

Recently, DLT from HLT&DLT was awarded an honorary certificate and a letter of appreciation from Shandong Hongbang Technology.

These two companies' first collaboration—the new-generation FoaMax 3-layer foam ceramic tunnel kiln project—achieved successful production in one time thanks to its innovative process and stable firing performance, delivering significant value and efficiency for Hongbang Technology.

During construction, the project coincided with the scorching summer season, posing multiple challenges. The company management rapidly allocated resources, synchronizing spare parts, personnel, and plans, while technicians worked 24-hour shifts to ensure smooth commissioning.

Thermal Engineer Mr. Jinxian CHEN, over 60, remained on the front line, hand-in-hand guiding technicians, achieving success in one time!

Engineer Mr. Jun LI, responsible for thermal, mechanical, and project management, worked through continuous night shifts to accelerate commissioning!

Electrical Engineer Mr. Zhiguang HE, managing mechanical, electrical, and piping tasks, handled issues on the spot—even eating a quick lunch with a single steamed bun!

Technician Mr. Tao WU decisively managed kiln emergencies during inspections, preventing losses for the customer!

DLT's performance speaks for itself, earning high customer praise for its technical strength, rapid response, and attentive service:

▲ Firing pass rate ≥ 99%;

▲ Maximum daily green body output ≥ 460 m³;

▲ Unit energy consumption for 12 cm thickness ≤ 75 m³ natural gas/m³ product, 20% gas savings and 25% electricity savings compared to similar machiner

▲ Single firing for 100–150 mm thick products;

▲ Cutting without chipping or burrs, smooth and precise;

▲ Foam ceramic boards of 1800×3000 mm, thickness 80–150 mm: bulk density 0.36–0.40 g/cm³, whiteness 36–40, compressive strength 7.5–9.5 MPa.

(HLT&DLT)

loading...

loading... 13 Oct 2025

13 Oct 2025