Technology comes first for achievement of green and sustainable development

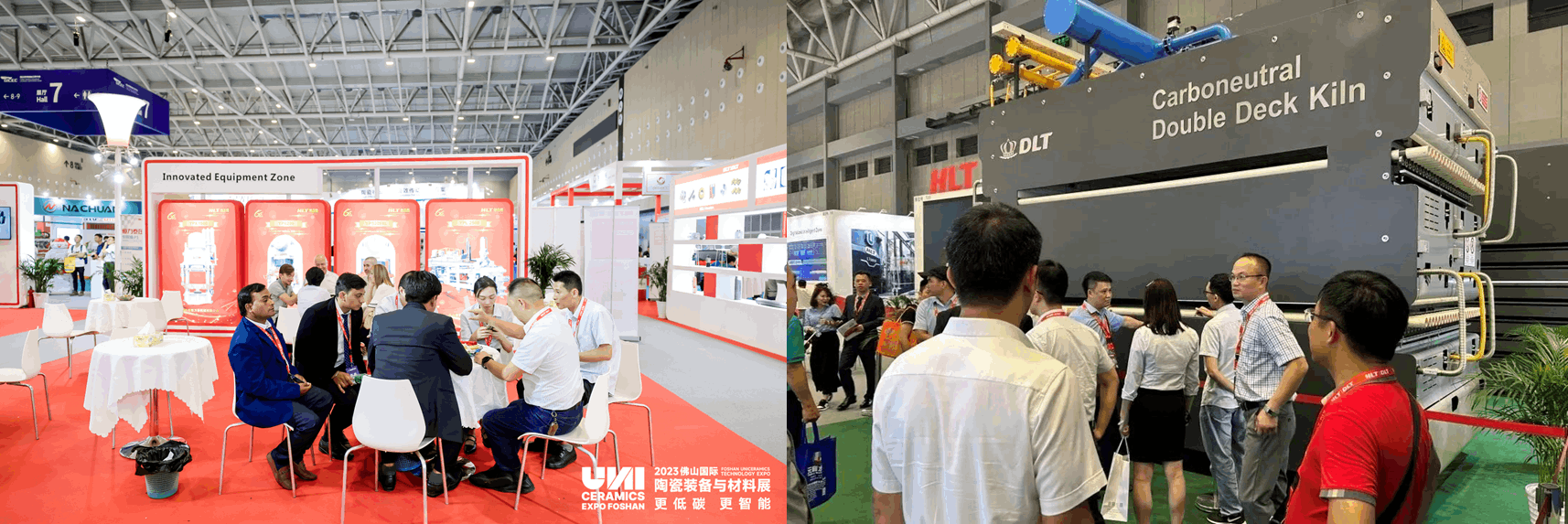

Six exhibiting sites of HLT&DLT Ceramics Machinery are used to exhibit and introduce advanced and popular professional machinery in the industry now: high-quality forming technology, whole production line machinery and equipment independently developed for ceramic raw materials, and smart and gas-saving thermal-energy equipment used in various fields, deliver overall solutions for building ceramics manufacturing to global customers, and assist in the new model of intelligent and low-carbon production.

HLT&DLT 4.0 intelligent central control system for the whole production line is a digital management system that integrates ceramic enterprise management with cloud computing. It is a whole line monitoring system for the operation of ceramics equipment, including pre-crushing system, pulping system, continuous ball mill system, pulverizing system, pressing and forming, multi-layer drying and firing kiln. The system realizes data collection, storage and processing of the entire ceramic production plant, injecting a flow of fresh vitality into the intelligent management.

Integrating domestic and foreign advanced technologies, the innovation power of HLT Technology's raw materials production line machinery is stimulated continuously to develop and launch ConTinuB series digital and energy-saving continuous pulping system and FaST series energy-saving spray pulverizing system. Significantly improving the single line production capacity of raw materials, the upgraded technology has also the features of energy conservation, high efficiency and high degree of automation, which can ensure the normal and stable operation of subsequent equipment and smooth mass production of the entire factory, and satisfy the industry's needs for green building ceramic products.

In addition to the intelligent and automatic hydraulic press for large-sized ceramic plates, innovation fruit of YP90 series automatic hydraulic press, and LT6809 automatic hydraulic press specialized in forming process, HLT Machinery has also showcased the latest presses for new energy materials and aluminum profiles. HLT presses are highly efficient in forming and able to deliver both thick or thin shaped bodies as required. The presses have maintained their advantages of high quality, stability and efficiency and won high praise and recognition from domestic and foreign customers.

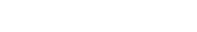

Carboneutral high-efficiency and energy-saving double-layer roller kiln for sintered stone is a new generation of Carboneutral double-layer roller kiln developed by DLT based on a combination of hands-on experience of more than 20 double-layer roller kilns, the advanced design concept of Italian ICF & Welko for double-layer kilns and the first-hand operation data of domestic kilns for sintered stone. Also on display are EM7 high-efficiency self-circulation seven-layer dryer, which combines the advantages of high efficiency, uniformity, high speed, energy conservation and strong adaptability to different products with numerous specifications and long drying cycle span, as well as new 3HP self-cleaning gas-gas heater.

Aiming at the disruptive key technology of zero-carbon combustion in ceramic kilns and to explore new directions for China's ceramic industry to achieve the carbon peak and neutrality targets, after nearly a year of technical research and innovation, DLT produced the world's first “zero-carbon fired ceramic tiles" in pilot scale at Oceano Experimental Center together with multiple institutions on December 23rd, 2022. The on-site testing by a third-party environmental impact assessment agency showed that the exhaust emissions of kiln were in full conformity with national standards. The second pilot test was completed successfully on April 18th and 19th, 2023.

(Huaying HUANG, HLT&DLT & Jiasheng XIE, President Office)

loading...

loading... 01 Jun 2023

01 Jun 2023